Apistek possesses comprehensive CFD thermal fluid simulation and system

thermal design capabilities.We can optimize the heat pipe routing and

structural layout based on the varying thermal loaddistribution, spatial

constraints, and component configuration of different products, ensuring

bothheat transfer efficiency and system stability.

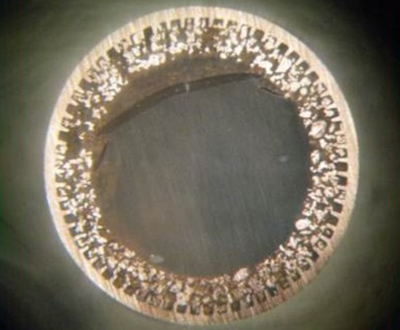

In the area of wick structure technology, we have manufacturing

capabilities for various forms, includingsintered copper powder wicks,

grooved wick structures, and copper mesh wicks. We can also design

composite wick structures according to different power densities and

application conditions, balancingboth heat conduction efficiency and

capillary return performance. This ensures that our heat pipes and

vapor chambers maintain stable performance under high tilt angles

and high heat flux environments.

Apistek possesses bending and forming along with special-shaped

heat pipe processing capabilities. We canproduce heat pipes with

outer diameters ranging from Ø5 to Ø12 mm, supporting various

special shapedesigns such as 3D bending, stepped flattening, and

C-type/U-type structures. This allows us to flexiblymeet diverse

customer requirements regarding system integration and structural

space. In addition toconventional thick heat plates—including

stamped copper plates, forged copper, and alloy materials—

we can develop hybrid integrated modules that combine heat

pipes and heat plates, effectively enhancingoverall cooling efficiency

according to customer's structural design needs.

We currently have the capacity for mass production of over 1 million

heat pipes per month. We haveestablished a complete internal

development process: from concept design →sample production

→thermal performance testing →reliability verification →

mass production deployment. This entire process is completed

within the same system, ensuring development timeline

efficiency and quality consistency.

Apistek has accumulated numerous patents related to heat pipe and

vapor chamber structures, covering areas such as wick structure design,

vacuum encapsulation, and high thermal conductivity material

application. Leveraging our profound R&D strength and complete

manufacturing processes, we help customers achieve product

differentiation and provide more competitive thermal solutions.

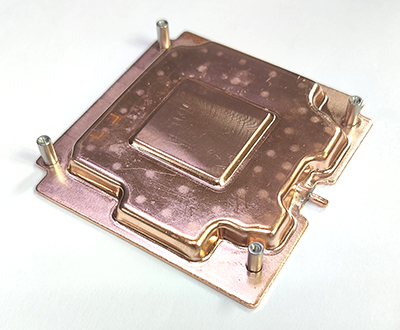

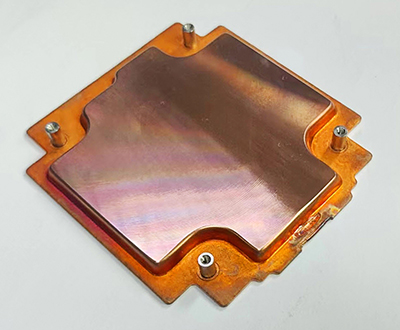

VC (Vapor chamber) for short, its function and working principle are the same as heat pipes, it is a vacuum cavity with microstructure on the inner wall, it uses the phase change evaporation of the cooling medium in the sealed space to quickly diffuse the heat into the cavity, After the working medium at the condensing end condenses into a liquid, it flows back to the heat source end through capillary force. This operation will be repeated in the cavity, which plays the role of rapid heat conduction.

The vapor chamber is a two-dimensional surface-to-surface heat conduction, and it is a device that can bring a point heat source to a large area for heat dissipation. Compared with the one-dimensional linear heat conduction of the heat pipe, the heat transfer efficiency of the vapor chamber is higher. Due to its good thermal conductivity, it is widely used in heat dissipation of electronic chips with high heat flux, such as smartphone chips, notebooks, servers and CPU/GPU of personal computers, etc.